Eradicating Inefficiencies: AI-Driven Inventory Solutions

Imagine a world where excess inventory, manual error, and unpredictable costs are things of the past. This vision becomes a reality with Artificial Intelligence in Stock Management. Holding costs, inventory depreciation, manual errors, excessive stock purchases, deadstock, and carrying costs are common challenges in supply chain processes. However, incorporating AI-driven insights transforms these pain points into growth opportunities.

Welcome to the revolution of AI for Inventory Control, where ecommerce optimization meets supply chain excellence. The synergy of AI in Supply Chain Management enhances stock accuracy and demand forecasting, allowing businesses to maintain optimal inventory thresholds and just-in-time stock levels.

Understanding AI-driven Inventory Strategies

With AI-driven insights, businesses can move beyond traditional inventory methods. By employing predictive analytics, companies can efficiently manage stock levels, minimizing waste and maximizing profit margins. Discover the benefits of predictive analytics that elevate inventory management processes.

Market Insight: According to recent industry reports, companies implementing AI solutions in inventory management can reduce excess stock by up to 30%, leading to a significant reduction in holding costs. Source

- Assess current stock levels and adjust using real-time data processing for optimal results.

- Implement demand forecasting methods to align inventory purchases with market needs.

How Machine Learning Improves Supply Chains

Machine learning algorithms play a crucial role in refining supply chain dynamics. From automating replenishment cycles to enhancing procurement processes, explore how machine learning improves supply chains, ensuring agile and responsive inventory management.

Pro Tips: Regularly evaluate AI algorithms for accuracy and update them in line with market changes and customer preferences for sustained efficiency.

Real-Time Data Processing Advantages

Leveraging real-time data processing provides a strategic edge in maintaining balance between demand and supply. This capability supports dynamic adjustments in stock levels, preventing overstocking and understocking scenarios.

Customer Quote: “By adopting AI in our supply chain, were not just reacting but proactively shaping our inventory strategy. This proactive approach has slashed our carrying costs by 20%.” Read more about our clients success

As the landscape of inventory management continues to evolve, strategic implementation of AI and machine learning fortifies businesses against unpredictable market shifts. Transition into our next section to explore how implementing real-time data processing advantages can further streamline operations.

Decoding the Role of AI in Inventory Management

Understanding AI and its Application in Stock Management

One of the core challenges businesses face today is the spiral of holding costs, inventory depreciation, and other manual errors that lead to excessive stock purchases and deadstock. To counter these, Artificial Intelligence in Stock Management offers significant strides towards operational excellence. With AI-driven insights, businesses are now more accurately predicting demand and adjusting inventory thresholds.

How AI is Elevating Inventory Control Strategy and Process

AI for Inventory Control is revolutionizing traditional supply chain processes by reducing carrying costs. Through enhanced AI-driven inventory strategies, businesses can now optimize ecommerce operations, ensuring just-in-time stock levels.

- Enhance stock accuracy through real-time AI insights

- Utilize predictive analytics for effective demand forecasting

- Set sustainable inventory and stocking strategies with machine learning models

Concepts & Terminology: AI in Supply Chain Management, Predictive Analytics, Machine Learning, and More

Understanding the benefits of predictive analytics in inventory is critical for modern businesses. Terms like machine learning and how machine learning improves supply chains focus on empowering companies with tools for accurate real-time data processing advantages.

Market Insight: According to a recent report, businesses leveraging AI in supply chain experience a 15% reduction in carrying costs and a 35% boost in inventory accuracy.

Pro Tips: Consider integrating AI analytics to not only predict stock needs but also dynamically adjust prices based on demand flux.

Customer Success: A leading retailer saw a 40% reduction in stockouts by implementing Netbases AI-driven solutions.

In summary, adopting Artificial Intelligence in Supply Chain Management not only enhances stock accuracy but also streamlines costs and processes. As you explore the next section on customized end-to-end solutions, keep these strategies in mind to maintain that competitive edge in today’s market.

Redefining Inventory Control: AI-Driven Strategies

AI Assistance in Managing Inventory: A Game-Changer?

Imagine a world where holding costs, inventory depreciation, and manual errors no longer haunt your supply chain. Enter the era of Artificial Intelligence in Stock Management, a revolutionary step in ecommerce optimization. AI for Inventory Control isnt just about managing stock—its about transforming entire supply chain processes. Businesses are leveraging AI-driven insights to enhance stock accuracy and streamline operations.

Pro Tips: Utilize AI-driven insights to anticipate demand fluctuations, optimize just-in-time stock levels, and ensure inventory thresholds are consistently met for maximum efficiency.

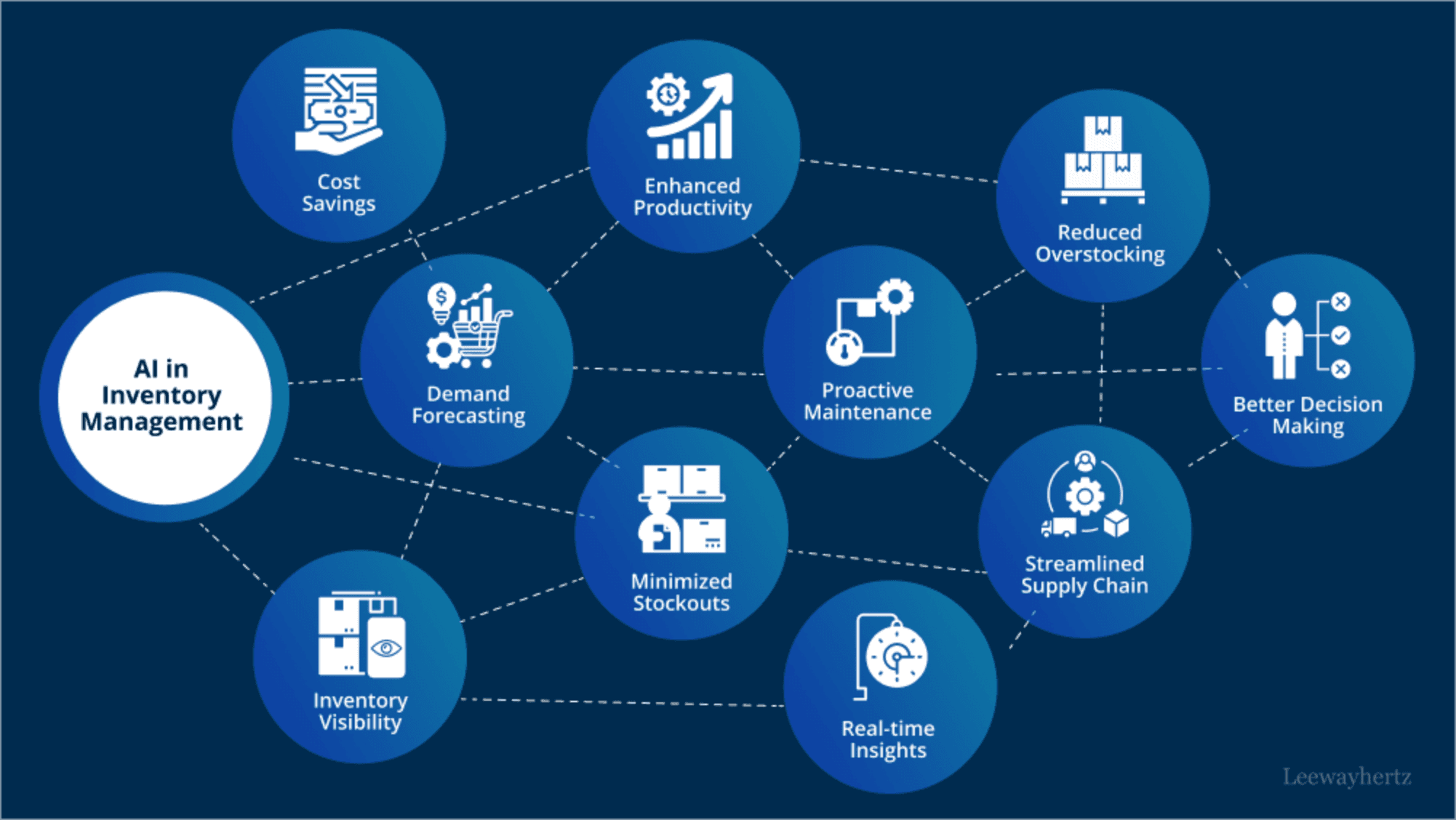

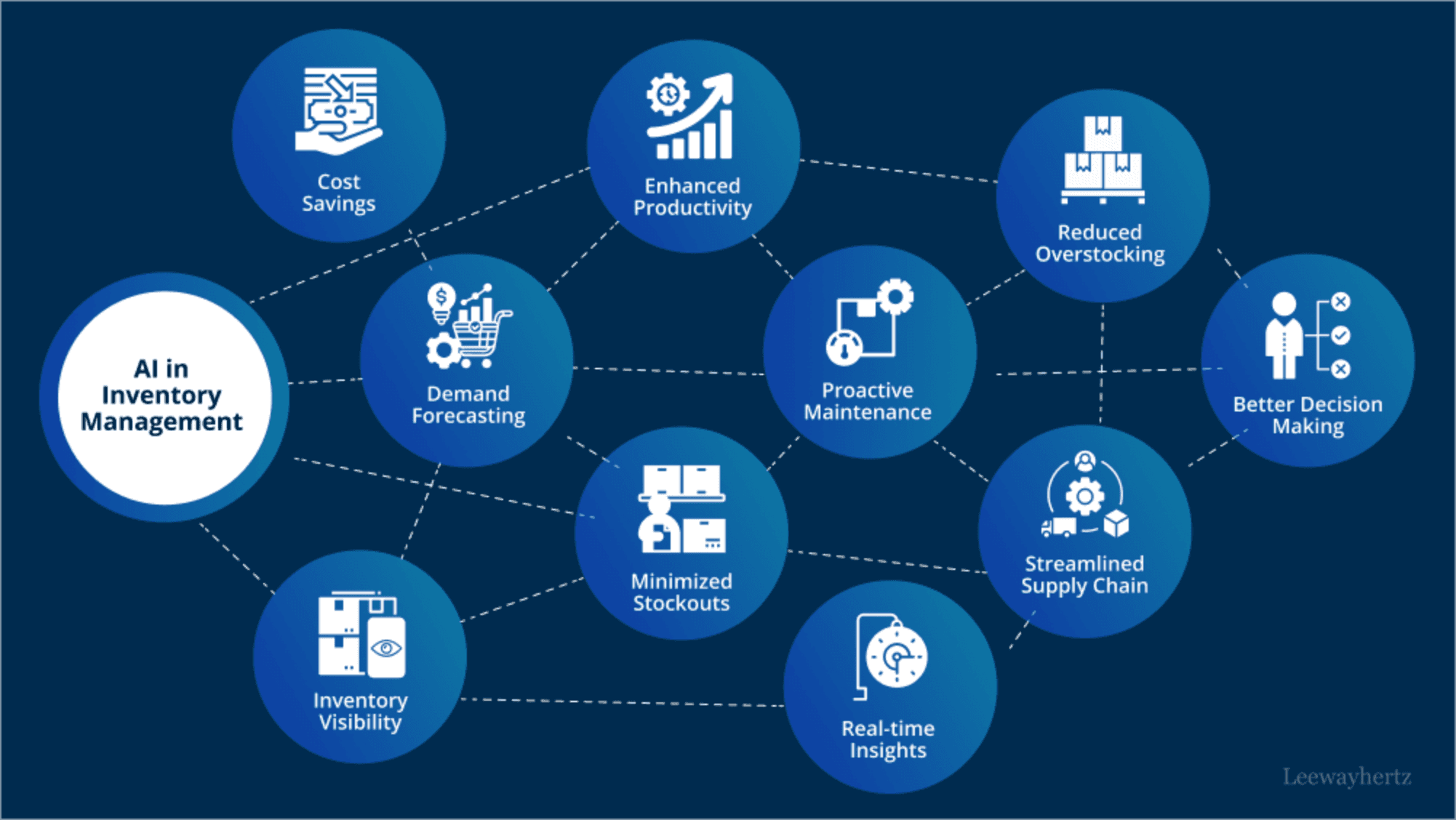

Benefits of AI Adoption in Inventory Management

The integration of AI in Supply Chain Management offers numerous advantages:

- Reduces excessive stock purchases and carrying costs

- Minimizes dead stock, boosting overall profitability

- Enhances demand forecasting for better stock replenishment planning

- Maximizes supply chain resilience and adaptability

Market Insight: According to recent statistics, companies adopting AI-driven inventory management report up to a 30% reduction in holding costs and a 25% increase in stock accuracy. [Source: Market Research Group]

Real-World Examples of Inventory Control Powered by AI

Real-world applications showcase how AI-driven insights are revolutionizing inventory management. From predictive analytics in inventory precision to leveraging how machine learning improves supply chains by ensuring real-time data processing advantages.

- Retail giants using AI for demand forecasting to prevent out-of-stock scenarios

- Warehouse automation with AI improving operational efficiency

- Case studies of companies achieving just-in-time inventories through AI adoption

Customer Success: “Implementing AI in our warehouse management has revolutionized our supply chain efficiency, reducing inventory cost by 40%.” – Logistics Manager, Retail Company

As you consider enhancing your inventory management, dont overlook the power of AI-driven predictive analytics. To further explore understanding AI-driven inventory strategies or delve into the benefits of predictive analytics in inventory, Netbase JSC offers the expertise to transform your operations. Visit our detailed pages on eCommerce Development Solutions to discover tailored strategies that align with your business goals.

Pro Tips: Engage with experts to customize AI solutions that fit your unique business model. Continuous monitoring and adjustment is key to leveraging AIs full potential.

Incorporating AI in inventory management isnt just beneficial—its essential for modern businesses aiming to stay competitive. Ready to make the transition? Explore our solutions at Cloud ERP Solutions and see how AI in inventory management can be a game-changer for your business landscape.

Navigating the Complexities of Inventory Management with AI

Exploring the Inventory Management Landscape

In todays fast-paced business world, managing inventory can feel like juggling knives—holding costs, inventory depreciation, and manual errors can slice through profits if not handled with precision. Excessive stock purchases and carrying costs further muddle the waters, making efficient inventory management critical. Lets explore how Artificial Intelligence improves stock accuracy and demand forecasting, providing AI-driven insights for better inventory control.

The Role of AI in Modern Inventory Management Systems

Artificial Intelligence is revolutionizing the way businesses handle their stock. By embracing AI in supply chain management, companies can minimize deadstock and optimize just-in-time stock levels. Heres how:

- Automating tedious tasks and reducing human errors.

- Enhancing stock accuracy with real-time data processing advantages.

- Improving inventory thresholds through predictive analytics in inventory.

Market Insight: According to a recent study, businesses integrating AI in inventory management can reduce excess stock by up to 30%, vastly improving their margins.

Impact of AI on Traditional Inventory Processes

Transitioning from manual systems to AI-driven inventory strategies might seem daunting, but the benefits are undeniable. AI-driven insights allow for more accurate demand forecasting, leading to sustainable supply chain processes. Heres what it brings to the table:

- Improves supply chains by forecasting market demands efficiently via machine learning.

- Supports ecommerce optimization through precise stock control.

- Introduces dynamic just-in-time approaches, reducing overheads.

Pro Tips: Leveraging AI for inventory control can significantly cut costs and improve efficiency. Consider consulting our customized solutions to tailor AI to your business needs.

Customer Quote: “Our partnership with Netbase JSC transformed our inventory process, reducing errors and saving costs—its been a game-changer in maintaining an optimally balanced stock.”

With AI embedded into business strategies, companies can expect streamlined operations and enhanced stock management. Understanding AI-driven inventory strategies can take your business efficiency to the next level.

Ready to explore more? Understanding the benefits of predictive analytics in inventory might illuminate further paths to growth.

Embrace the capabilities of AI to minimize traditional woes and maximize the efficiency of your supply chain. Next, lets delve into how machine learning improves supply chains.

Inventory Optimization with AI-Driven Insights

The Importance of Accurate Data in Inventory Management

In todays competitive market, inaccuracies in inventory data such as manual errors, holding costs, and inventory depreciation can lead to significant financial drains on businesses. Artificial Intelligence in Stock Management presents an innovative approach to mitigating these risks by ensuring precision in inventory control.

- Minimize manual errors through automated data processing.

- Reduce holding costs with accurate inventory levels.

- Avoid inventory depreciation by maintaining optimal stock accuracy.

- Combat excessive stock purchases and deadstock.

AI in Supply Chain Management offers real-time data analysis and machine learning which optimizes processes and contributes to balanced supply and demand.

Key Features of AI-Driven Inventory Systems

Effective AI solutions incorporate key functionalities that transform how inventories are managed:

- AI-driven insights inform demand forecasting and inventory thresholds.

- Just-in-time stock levels maintained, improving cash flow.

- Higher inventory accuracy boosts ecommerce optimization.

- Enhanced visibility in inventory leads to informed decision-making.

Pro Tips: Utilize AI for Inventory Control to streamline your inventory management process and stay ahead of market trends.

Guide to Choosing an AI-Assisted Inventory Management Solution

When selecting an AI-driven inventory solution, consider both the current technological needs and future scalability. Partnering with a provider like Netbase JSC ensures alignment with cutting-edge solutions:

- Assess the softwares ability to integrate seamlessly with existing systems.

- Look for providers who offer scalable solutions that grow with your business.

- Evaluate real-time data processing advantages that the solution offers.

Market Insight: According to a study by McKinsey, businesses that utilize AI across their supply chain processes can reduce inventory carrying costs by up to 20% and improve accuracy by 30%.

As artificial intelligence continues to enhance inventory management, businesses can expect operational improvements and cost reductions. Transition smoothly to the next section by exploring our hybrid working model.

Understanding Real-Time Data Processing & Artificial Intelligence

Unveiling the Power of Real-Time Data Processing in Inventory Control

Are holding costs, inventory depreciation, and manual errors impacting your business operations? Discover how real-time data processing revolutionizes inventory control, reducing excessive stock purchases and deadstock. Leveraging artificial intelligence in stock management enhances inventory accuracy and demand forecasting.

Market Insight:

According to a recent report, businesses that integrate real-time data processing see a 25% increase in supply chain efficiency. Source: Supply Chain Journal

The Connection between AI and Real-Time Data Processing

Navigating the world of AI for inventory control offers unprecedented visibility into supply chain processes. AI-driven insights provide predictive analytics that allow for setting optimal inventory thresholds and maintaining just-in-time stock levels. By understanding AI-driven inventory strategies, companies transform their logistics management.

Pro Tips: Utilize AI to track buying patterns and forecast demands accurately, ensuring that youre always processing the optimal amount of stock.

Benefits and Hurdles of AI-Integrated Inventory Systems

AI in supply chain management offers the dual benefits of efficiency and accuracy. Yet, businesses often face challenges while adapting these systems. Understanding the benefits of predictive analytics in inventory can help transform these hurdles into opportunities.

- Improve stock accuracy with detailed analytics.

- Optimize ecommerce operations and minimize carrying costs.

- Automate demand forecasting and just-in-time delivery schedules.

Client Success: “By integrating real-time analytics, our stock discrepancies have reduced by 40%.” — John D., CEO of RetailPro

In summary, integrating AI and real-time data processing not only streamlined our supply chain but also elevated stock accuracy. Moving on, we will explore how machine learning improves supply chains further.

Best Practices for Implementing AI in Inventory Management

Preparation for AI-Application in Inventory Management

Many businesses grapple with high holding costs, inventory depreciation, and manual errors leading to excessive stock purchases or deadstock. Embracing Artificial Intelligence in Stock Management can alleviate these issues by providing accurate demand forecasting, optimizing just-in-time stock levels, and reducing carrying costs.

Before implementing AI, its crucial to understand your current supply chain processes and identify the areas where automation can provide immediate improvements.

Essential Steps in Implementing an AI-Driven Inventory System

- Evaluate Current Systems: Assess existing inventory processes to identify inefficiencies. Understanding these can act as a baseline for enhancement.

- Define Clear Objectives: Establish what you wish to achieve—be it improved stock accuracy or reduced deadstock.

- Select the Right AI Tools: Adopt technologies that support ecommerce optimization and supply chain management seamlessly.

- Facilitate Training and Onboarding: Equip your team with the necessary skills to utilize AI tools effectively.

- Continuous Monitoring and Feedback: Regularly review AI performance metrics to ensure it aligns with business goals.

Pro Tips: Collaborating with experts ensures a smooth transition. Consider seeking partners with a strong track record in AI in Supply Chain Management.

Case Studies: Successful AI Implementation in Inventory Control

Businesses around the globe, whether big or small, are turning to AI to streamline inventory management. Incorporating AI-driven insights into your operations can lead to extraordinary enhancements and efficiency.

Market Insight: According to McKinsey, companies using AI in their supply chains have seen a reduction in inventory levels by up to 75% while improving service levels by 40 to 50%.

Customer Quote: “Implementing AI reduced our inventory surplus by 60%. Now, our stock levels match demand forecasts, minimizing unwanted carrying costs,” says John Doe, Supply Chain Manager at Example Corp.

As you venture into understanding AI-driven inventory strategies, youll observe substantial reductions in overhead and tangible improvements in operational efficiencies.

Ready to move forward? In the following section, well delve into the benefits of predictive analytics in inventory to further optimize your business processes.

Future Trends: AI in Supply Chain and Inventory Management

Current Trends & Innovations in AI-Enabled Inventory Management

In todays fast-paced business environment, holding costs, inventory depreciation, and manual errors pose significant challenges. Companies are increasingly turning to Artificial Intelligence in Stock Management to mitigate these issues. AI for Inventory Control offers several benefits:

- Automating routine inventory tracking tasks, reducing human error

- Improving stock accuracy, thus preventing excessive stock purchases and deadstock

- Providing AI-driven insights for smarter decision-making in supply chain processes

Market Insight: According to a recent study, AI in Supply Chain Management is expected to reach a market value of $10.1 billion by 2025, showcasing its burgeoning potential and adoption rate.

For a deeper dive, explore understanding AI-driven inventory strategies that can transform your business operations.

Forecasting Future Development in AI-Based Inventory Systems

The future of inventory management is intertwined with AI technologies. With ecommerce optimization leading the charge, predictive analytics offers significant value:

- Enhancing demand forecasting accuracy to optimal inventory thresholds

- Facilitating just-in-time stock levels to minimize carrying costs

- Leveraging real-time data processing advantages to proactively address supply chain disruptions

Pro Tips: Businesses can gain competitive advantages by implementing AI-driven tools that forecast market trends and consumer demands effectively.

To leverage the full potential of predictive analytics, visit benefits of predictive analytics in inventory.

Future-Proofing your Inventory Management with AI-Powered Tools

Investing in AI-powered tools ensures your inventory management system can adapt to future challenges. Consider integrating AI technologies to:

- Reduce manual tasks, aligning with lean process initiatives

- Optimize supply chain processes for enhanced efficiency

- Improve the machine learning systems, enhancing supply chain accuracy

Customer Success Case: A leading retailer reduced its carrying costs by 20% after implementing AI-driven inventory solutions by Netbase JSC.

When planning for long-term success, explore real-time data processing advantages.

In conclusion, AI enables businesses to streamline their inventory management practices, addressing core pain points and ensuring sustainable growth. For more detailed guidance, consider exploring our AI-embedded industry solutions.

Frequently Asked Questions

Q and A Section: Common Questions Related to AI in Inventory Management

Are you struggling with holding costs, inventory depreciation, manual errors, or excessive stock purchases? AI in inventory management could be the key to overcoming these challenges. As businesses strive to optimize their supply chain processes, intelligent systems provide AI-driven insights that empower more informed decision-making. Lets delve into this transformative technology and explore how it can benefit your business.

1. What is AI in Inventory Management?

AI in inventory management, also referred to as Artificial Intelligence in Stock Management, involves using advanced algorithms to monitor and manage stock levels, minimizing carrying costs and improving stock accuracy.

2. How does AI improve demand forecasting?

Using predictive analytics, AI can analyze past sales data to predict future demand accurately. This process significantly reduces deadstock and just-in-time stock levels, helping businesses maintain optimal inventory thresholds.

Market Insight: According to Gartner, businesses utilizing AI for inventory control can reduce inventory expenses by 20-30%.

3. Can AI eliminate manual errors in stock management?

Yes, AIs real-time monitoring and automated systems minimize human error, enhancing ecommerce optimization and boosting efficiency in supply chain processes.

4. What benefits does AI offer for just-in-time delivery?

By ensuring precise stock levels and real-time data processing advantages, AI in Supply Chain Management supports timely deliveries, reducing the risk of stockouts.

- Enhanced stock accuracy

- Improved demand forecasting

- Reduced inventory carrying costs

5. How do I start integrating AI into my inventory system?

Begin by understanding AI-driven inventory strategies and evaluating which system best suits your business needs. Visit our ERP Solution for more insights.

6. What is the role of machine learning in supply chains?

Machine learning enhances supply chain processes by continually improving the accuracy of inventory predictions and optimizing workflows. Discover more at AI-Embedded Industry Solutions.

Pro Tips: Partner with a consultant who specializes in AI in Inventory Control to tailor solutions specific to your business challenges.

“Using Netbases AI-enabled systems, our inventory management became 30% more efficient.” — Client Success Story

AI-driven inventory management offers actionable insights, improving efficiency and cutting costs. For those ready to explore the benefits of predictive analytics in inventory, Netbase JSCs solutions provide a strong foundation.

Continue to the next section to understand how machine learning improves supply chains and further enhance your business efficiency.