Mastering Intelligent Process Automation: A Guide to Streamlining Supply Chain Operations

Turbocharge Your Supply Chain: What if you could leverage artificial intelligence to minimize inefficiencies and optimize logistics?

Repetitive tasks and cumbersome processes bottleneck your supply chains performance. Imagine automating repetitive tasks to increase speed and accuracy, predicting demand to reduce overstock and stockouts, and optimizing transport routes to minimize delivery times. These are not just dreams but achievable goals with advances in Intelligent Process Automation (IPA).

Automate and Accelerate: Leveraging Intelligent Automation

Intelligent Automation technologies can transform supply chain dynamics:

- Automate data entry and order management to boost operational speed.

- Optimize inventory levels using predictive analytics for inventory management.

- Enhance workflow efficiency while significantly reducing human error through automation.

Market Insight: Companies that leverage AI technologies for supply chain optimization see a reduction in logistics costs by up to 30%. (Source)

Predictive Insights for Inventory Optimization

Utilizing advanced analytics for demand forecasting allows organizations to:

- Enhance supply chain responsiveness through real-time demand prediction.

- Monitor stock levels accurately, mitigating risks of overstock and stockouts.

Pro Tips: Implementing predictive insights can help streamline order management processes, ensuring timely delivery and customer satisfaction.

Optimizing Logistics with Machine Learning

By harnessing machine learning, you can:

- Predict optimal transport routes, saving time and lowering fuel costs.

- Minimize delivery times to meet customer expectations more effectively.

AI-enabled logistics optimization has the capability to improve delivery accuracy by up to 25%. Proven Success: A Netbase client experienced this efficiency firsthand, leading to significant operational cost savings.

Your journey toward a robust and AI-powered supply chain doesnt end here. Discover how IPA improves supply chain operations by diving into the benefits of automation in supply chains and predictive analytics for inventory management as we explore more innovative ways to enhance your logistics strategy.

Deciphering Intelligent Process Automation

The Concept of Intelligent Process Automation Explained

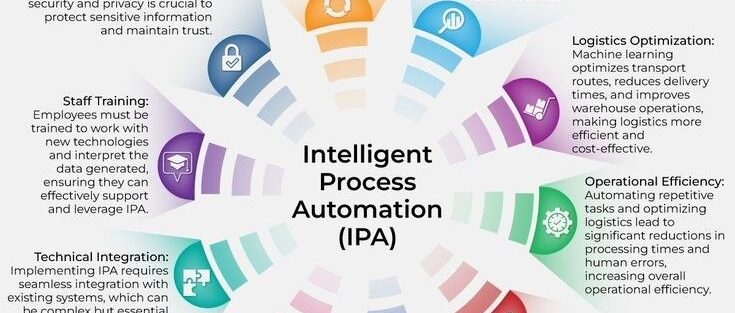

Imagine streamlining operations by using repetitive task automation to enhance speed and accuracy. This is where Intelligent Process Automation (IPA) comes into play. By combining software robots with intelligent automation, businesses can revolutionize data entry processes, order management, and invoicing. As a result, companies can focus more on strategic tasks and less on mundane activities.

The Emergence of IPA in Todays Tech-Driven World

In our technology-driven era, the emergence of IPA has become inevitable. Intelligent Automation infuses analytics and machine learning into business processes, transforming how companies operate. By integrating data entry automation and demand prediction, businesses are leapfrogging into operational excellence.

Market Insight:

According to a Gartner study, by 2024, organizations using process automation and intelligence will reduce operational costs by 30%.

Terminology: Understanding IPA, Intelligent Automation, and Process Automation

To fully grasp the significance of process automation, understanding the terminology is essential. IPA stands for Intelligent Process Automation, a suite of technologies including software robots and data automation, aimed at optimizing logistics with machine learning. It supports activities such as stock level monitoring and transport route prediction, ensuring timely deliveries and accurate demand forecasting.

- Adopt IPA to improve supply chain operations

- Invest in software solutions that enhance workflow efficiency

- Explore predictive analytics for inventory management to mitigate overstock and stockouts

- Utilize machine learning to forecast demand and route optimization

Pro Tips: For businesses looking to integrate IPA, consider starting small with data-intensive tasks like invoicing automation and gradually scale to more complex operations such as delivery time minimization. This phased approach ensures a smoother transition and better results.

Success stories abound. One such client leveraged custom e-commerce development to integrate intelligent automation, reducing processing time by 40% while enhancing accuracy. You too can harness these tools to reinvent process management.

In conclusion, IPA not only addresses the immediate need to reduce human error through enhancing workflow efficiency but also provides a pathway to achieve long-term operational efficiency. As we pivot towards the next section, consider exploring ways this technology can be tailored to meet your specific business needs.

Revolutionizing Supply Chain with IPA

What is IPAs Role in Supply Chain Management?

Repetitive task automation to increase speed and accuracy is crucial in todays fast-paced market. Intelligent Process Automation (IPA) revolutionizes supply chain management by enhancing workflow efficiency and significantly reducing human error. By integrating software robots for data entry automation and order management, businesses streamline processes that were previously time-consuming and error-prone.

Market Insight: According to a recent study, 64% of manufacturers have reported that digital transformation in supply chain processes led to higher accuracy and significant cost reductions.

Key Benefits of Integrating IPA into Supply Chains

If youre looking to enhance how IPA improves supply chain operations, implementing IPA can be transformative. Here are some key benefits:

- Demand forecasting to reduce overstock and stockouts, leading to more effective inventory optimization.

- Optimizing transport routes to minimize delivery times, using state-of-the-art delivery time minimization.

- Improving order management and invoicing automation, which enhances cash flow and operational efficiency.

Pro Tips: Consider leveraging predictive analytics for inventory management to mitigate risks associated with stock level monitoring.

Exploring Real-Life Examples of IPA in Supply Chain Management

Companies around the globe are embracing the benefits of automation in supply chains. Lets explore some real-life cases:

- A leading retailer used demand prediction to optimize their inventory, resulting in a 25% reduction in stale inventory.

- A global logistics company implemented transport route prediction, reducing transit time by up to 30%.

Customer Success: “By integrating IPA, our delivery accuracy increased by 40%, and customer satisfaction soared,” shares a well-known supply chain manager.

Optimizing logistics with machine learning isnt just about technology; its about transforming your entire business strategy to meet market demands more efficiently and effectively.

Intelligent Process Automation is not just a tool; its a strategic partner in transforming supply chain management. As you navigate through the complexities of modern supply chains, embrace the power of IPA to drive your business forward.

Inside the Supply Chain Ecosystem

Appreciating the Complexities of the Supply Chain Ecosystem

In the dynamic world of supply chain management, businesses often grapple with challenges such as repetitive tasks, demand forecasting inaccuracies, and inefficient transport routes. By employing Intelligent Process Automation (IPA), you can streamline operations, enhance speed and accuracy, and drive demand prediction with precision. Our solutions pave the way for breakthroughs in optimizing logistics with machine learning.

IPAs Position in the Supply Chain Framework

IPA, through its innovative technology like software robots, seamlessly integrates into traditional workflows, ensuring data entry automation, effective order management, and precise invoicing. This transformative approach not only boosts speed but also minimizes human error. Discover how how IPA improves supply chain operations can revolutionize your business processes.

Market Insight: The implementation of process automation can lead to a reduction in operations costs by up to 30% according to a recent industry report.

Impact of IPA on Traditional Supply Chain Processes

Transitioning from traditional methods, businesses report significant progress in workflow efficiency. Automation facilitates demand prediction to control inventory levels and prevent overstocking, while software innovations refine transport route prediction for timely deliveries. Our focus on predictive analytics for inventory management ensures that your stock level monitoring is always optimal.

- Utilize IPA for automating routine tasks

- Leverage intelligent solutions for better demand forecasting

- Enhance logistics with precise transport route optimization

Pro Tips: Regularly update your automation processes to adapt to market changes and customer needs for maximum effectiveness.

“Implementing Intelligent Process Automation has tremendously improved our order accuracy and reduced delivery times,” says a satisfied client from the logistics sector, showcasing the practical benefits of automation.

In summary, embracing IPA can significantly strengthen and transform your supply chain ecosystem, aligning with modern business demands. Explore the benefits of automation in supply chains today for a competitive edge. Transition to our next section on Internet of Things development services to discover more opportunities for innovation.

Harnessing the Power of Robotic Process Automation

Understanding the Concept of Robotic Process Automation

Repetitive task automation in supply chains is a key driver for increased speed and accuracy. RPA—Robotic Process Automation—utilizes software robots to handle mundane tasks such as data entry automation and order management, freeing human resources for more strategic activities. This intelligent automation encompasses a breadth of activities including invoicing automation and stock level monitoring, making workflows more efficient and reducing human error significantly.

Leveraging RPA can vastly enhance demand forecasting, leading to a reduction in overstock and stockouts. For more on how IPA improves supply chain operations, check out our solutions.

Industry Applications of RPA in Supply Chain

- Demand prediction and inventory optimization help in aligning supply with market needs.

- Software robots can facilitate order management processes, thus improving operational efficiency.

- Invoicing automation to speed up financial workflows and reduce errors.

- Transport route prediction to optimize logistics and minimize delivery times.

Market Insight: According to a recent study, 79% of companies implementing RPA in the supply chain reported faster processing times and improved accuracy.

RPAs robust capabilities provide an edge in optimizing logistics with machine learning, allowing businesses to focus on strategic initiatives. Explore benefits of automation in supply chains with us.

How to Choose an RPA Platform for Optimizing Supply Chain Tasks

The decision to choose an RPA platform requires understanding your business needs and potential tech partners. Key points to consider include the platforms capability for intelligent automation, compatibility with existing systems, and scalability. Moreover, assessing its effectiveness in supporting demand prediction and enhancing stock level monitoring is crucial.

A well-chosen platform optimizes transport routes and minimizes delivery times, ensuring customer satisfaction and operational excellence. Discover how we can help with predictive analytics for inventory management.

Pro Tips: Engage with vendors to get custom demos, assessing flexibility and security features. Customer success stories can offer insights into the real-world effectiveness of RPA technologies.

“Implementing RPA with Netbase JSC led to a 50% reduction in processing time and improved our demand forecasting accuracy by 30%,” – A satisfied client.

Adopting an RPA platform can transform your supply chain, aligning operations with market dynamics to drive competitive advantage. Transition into technologies shaping the future—learn more at our main website.

Predictive Analytics: A Game Changer in Logistics

Defining Predictive Analytics in the Logistics Context

Predictive analytics in logistics applies advanced algorithms to forecast outcomes such as delivery times and demand fluctuations. This technology enables businesses to transition from reactive strategies to anticipatory logistics management. By doing so, logistics companies can significantly reduce human error and optimize operational efficiency. For further information on how IPA improves supply chain operations, consider exploring our detailed resources.

Significance of Predictive Analytics in Logistics Optimization

In the logistics sector, predictive analytics is a game-changer, addressing common challenges like inventory management and transport inefficiencies. This approach helps in demand prediction, inventory optimization, and transport route prediction, ultimately reducing overstocking and minimizing delay times. Leverage offerings such as predictive analytics for inventory management to ensure seamless operations.

Market Insight: According to a 2023 industry report, companies utilizing predictive analytics in logistics can reduce operational costs by up to 25% while improving delivery time efficiency by 30%.

Challenges and Solutions in Implementing Predictive Analytics

Implementing predictive analytics in logistics comes with its share of challenges, including data management and the integration of software robots. However, solutions like intelligent automation and process automation streamline order management and invoicing. For actionable advice on overcoming these obstacles, explore the optimizing logistics with machine learning section.

- Adopt intelligent automation to handle repetitive tasks and increase accuracy.

- Utilize demand prediction tools to maintain optimal stock levels and prevent stockouts.

- Integrate software robots for efficient order and data entry management.

Pro Tips: Start by digitizing your data and gradually introduce IPA technology for seamless transition and greater efficiency.

The benefits of automation in achieving logistics optimization are clear, offering both improved accuracy and efficiency. As you delve deeper into digital transformation, consider reviewing our case studies on benefits of automation in supply chains to glean insights from industry leaders.

Customer Success: “Implementing predictive analytics reduced our delivery time by 20%, enhancing customer satisfaction,” reports a leading retail partner using our services.

In summary, predictive analytics not only enhances logistics operations but also provides a competitive edge in the market. For those interested in diving into specific technologies such as machine learning or IoT development, head over to our IoT Development page.

Key Insights for Implementing IPA in Supply Chain Systems

Strategies for Successful IPA Implementation

Repetitive task automation to increase speed and accuracy is essential in todays competitive supply chain environment. Businesses strive to leverage Intelligent Automation (IPA) to streamline operations, improve how IPA improves supply chain operations, and reduce costs.

Market Insight: According to recent studies, companies implementing IPA can see up to a 30% increase in operational efficiency within the first year (source).

- Focus on data entry automation and order management to free up valuable human resources.

- Optimize transport routes to minimize delivery times and costs.

- Deploy software robots for routine tasks to reduce human error.

Step-by-step Guide to Deploying IPA in Supply Chain Operations

Embarking on the journey to deploy Intelligent Automation starts with understanding your processes. Heres a step-by-step approach:

- Identify key areas that can benefit from automation, such as invoicing automation and stock level monitoring.

- Engage with experts who can offer insights and customize solutions to suit your specific needs.

- Integrate predictive analytics for inventory management to ensure optimal stock levels and avoid overstock or stockouts.

Pro Tips: Collaborate with solution providers to get tailored advice that suits your industry. Contact our team for solutions at NetbaseJSC Contact.

Case Studies on Successful IPA Integrations in Supply Chains

Several businesses have reaped considerable rewards from IPA. A notable case involves a leading distributor that implemented demand prediction tools, drastically reducing delivery times.

Customer Quote: “Netbases automation solutions have transformed our workflow efficiency, allowing us to achieve new levels of precision and productivity.” – Stated by a satisfied client.

Success stories like optimizing logistics with machine learning highlight how intelligent systems can turn challenges into opportunities.

In closing, leveraging intelligent automation solutions not only addresses immediate operational pain points but also places businesses on a forward path towards sustainable growth. To delve deeper into our tailored solutions, visit our Custom Solutions Page.

The Future of AI and Automation in Supply Chain Management

Current Trends and Innovations in Supply Chain Automation

In todays fast-paced business environment, companies are turning to repetitive task automation to increase speed and accuracy, demand forecasting to reduce overstock and stockouts, and optimizing transport routes to minimize delivery times. This has led to an increase in the utilization of Intelligent Process Automation (IPA), leveraging technologies such as software robots and data entry automation, substantially enhancing workflow efficiency and reducing human error.

Businesses are experiencing firsthand how how IPA improves supply chain operations, leading to significant gains in efficiency and productivity.

Predicted Future Developments in AI-facilitated Supply Chains

AI is predicted to further revolutionize supply chains by enabling smarter demand prediction, inventory optimization, and stock level monitoring. The integration of machine learning for predictive analytics for inventory management allows businesses to proactively adjust their operations in real-time, minimizing disruptive stockouts and costly overstocks.

Market Insight: By 2025, AI technologies are expected to automate up to 70% of supply chain tasks, considerably minimizing manual intervention and enhancing operational efficiency.

How to Future-Proof your Supply Chain with IPA

Future-proofing your supply chain involves adopting IPA and intelligent automation practices that align with business goals. This ensures not only current operational efficiencies but also resilience against future disruptions.

- Implement software robots for repetitive, time-consuming tasks like order management and invoicing automation.

- Adopt demand prediction and inventory optimization strategies to balance supply and demand efficiently.

- Utilize transport route prediction and delivery time minimization to enhance logistics operations, reducing costs and improving customer satisfaction.

- Explore Netbases expertise in IPA solutions for tailoring specific needs and future-proofing strategies.

optimizing logistics with machine learning techniques can provide organizations with robust, scalable solutions tailored for the complexities of modern supply chains.

Pro Tips: Consulting with Netbase JSC experts can provide your business with specialized IPA solutions designed to enhance supply chain visibility and agility.

“Since implementing Netbases solutions, weve significantly cut down on delivery times and reduced our stockouts by 30%, transforming our supply chain management.” — Success Case: A Leading Retailer

In summary, embracing the trifecta of Intelligent Automation, AI, and machine learning in supply chains is no longer optional—its imperative. Transition smoothly by leveraging expert solutions from Netbases customized end-to-end solutions. Next, well explore real-life application scenarios to illustrate these strategies in action.

Frequently Asked Questions

Q&A Style Section: Exploring Intelligent Process Automation in Supply Chain Management

Are you struggling with repetitive task automation that drains your resources? Or perhaps incorrect demand forecasting leads to overstock and stockouts, hurting your efficiency? Learn how Intelligent Process Automation (IPA) could be your game-changer.

Top Questions on Intelligent Process Automation and Supply Chain Management

- How does IPA improve supply chain operations?

IPA streamlines supply chain processes by leveraging software robots for data entry automation, enhancing order management, and refining invoicing processes. Discover its potential in our ERP solutions. - What are the benefits of automation in supply chains?

By reducing human intervention, automation minimizes errors and increases process speed, ensuring accuracy across your operations. Learn more through our custom e-commerce solutions. - How does predictive analytics for inventory management work?

Predictive analytics helps in demand prediction to avoid overstock and stockouts, optimizing inventory and stock level monitoring for seamless operations. - How can logistics be optimized with machine learning?

Machine learning aids in transport route prediction and delivery time minimization, enhancing logistics efficiency. Check out our comprehensive tools at Cloud Management Development.

Market Insight: According to Market Research, the global IPA market is expected to grow at a CAGR of over 13% from 2021 to 2028, driven by increasing demand for business process automation and efficiency enhancement.

IPA is not just about quick wins; it offers significant long-term benefits such as enhanced workflow efficiency and reduced human error, supporting your strategic goals.

Pro Tips: Start small with pilot projects to gradually scale IPA initiatives across your supply chain. Focus on automation areas with the highest return on investment to optimize results.

Customer Quote: “Implementing IPA drastically reduced our operational costs and improved our demand forecasting accuracy by 40%,” said a leading retail logistics manager who transformed their supply chain with Netbase’s solutions.

With IPA, you can transform operations to not only keep up with the ever-changing market demands but stay one step ahead. Explore how we can help optimize logistics and enhance your supply chains efficiency with our solutions by visiting Netbase JSC.

Ready to dive deeper into how IPA can improve your business outcomes? Check out our section on the how IPA improves supply chain operations.

Embrace these automation solutions and witness seamless integration, informed decisions, and transformative growth for your supply chain.