How Businesses Use Artificial Intelligence to Transform Inventory Management and Supply Chains

In the fast-paced business world, rapidly adopting new technology is crucial to thrive. Artificial Intelligence (AI) in inventory management represents a transformative step towards enhanced efficiency and adaptive supply chains. Lets delve into how businesses can leverage AI innovation to revolutionize their inventory systems.

Understanding AI in Inventory Management Trends

Artificial Intelligence in Inventory is not just a buzzword; its a key to unlocking robust business operations. With AI, companies gain unrivaled insights and predictive capabilities which streamline processes and reduce errors.

- Enhance demand forecasting and reduce stockouts.

- Automate reorder processes to optimize inventory levels.

- Utilize Machine Learning in Inventory Control for real-time data analysis.

Pro Tips: Consider integrating AI-driven inventory management systems to reduce overhead costs and improve accuracy. For tailored solutions, visit our ERP solution page.

How AI is Transforming Supply Chains

Navigating digital transformation in your supply chain is vital. AI for inventory systems facilitates intelligent logistics planning and inventory accuracy enhancing overall business capabilities.

- Enhance supply chain visibility.

- Improve supplier collaboration through shared AI insights.

- Accelerate response times to market changes.

Market Insight: AI in supply chain management is set to grow with a CAGR of over 39% by 2027, reshaping how businesses operate globally—underscoring the importance of integrating AI strategies early.

Future of Inventory Management with AI

Embracing AI translates to achieving substantial operational scalability and intelligent resource management.

- Reduce human errors through automated systems.

- Benefit from high-tech inventory analytics.

- Employ smart shelving and robotics for optimized storage.

Pro Tips: AI-enhanced solutions open a pathway to a streamlined, efficient, and future-ready supply chain. Explore solutions at the AI embedded industry solutions page.

Market Projections for AI in Inventory Control

Most businesses report increased efficiency and productivity within the first year of adopting AI-integrated inventory systems.

- Strategically plan digitalization of supply chain processes.

- Lead within competitive markets backed by predictive AI analysis.

- Proactively manage threats and responses across logistics.

Pro Tips: Transitioning to AI-based systems can eliminate traditional barriers and accelerate growth. For more on our custom solutions, check our e-commerce development solutions.

“Implementing AI-driven inventory management was a game-changer for our logistics efficiency.” – Client Testimonial

To continue understanding how AI can propel your business forward, explore customized end-to-end solutions that meet your specific needs.

Unpacking AI in Inventory Management

Overview of AI in Inventory Management

The rapid adoption of new technology is crucial for businesses aiming to maintain a competitive edge. Digital transformation in the supply chain is no exception, especially in inventory management. Artificial Intelligence (AI) in inventory management is revolutionizing the way businesses operate by providing real-time insights and automating processes.

- Optimize stock levels automatically

- Predict future demand with precision

- Reduce operational inefficiencies significantly

Market Insight: According to recent studies, businesses that implement AI in inventory management see an average efficiency increase of 25%.

AI for Inventory Systems enables retailers and supply chain managers to leverage machine learning and analytics, ensuring smarter and more strategic inventory control. For detailed strategies on applying AI, visit our AI Embedded Solutions.

Decoding AIs Role in Modernizing Inventory Systems

Machine Learning in Inventory Control is bridging the gap between traditional practices and the need for scalability. By adopting AI technologies, businesses can soar past previous limitations, allowing them to scale effortlessly and address common barriers to AI adoption.

Pro Tips: Incorporate AI-based forecasting tools to anticipate market demand shifts and adjust your inventory dynamically.

The link between Artificial Intelligence and Inventory Control is evident when considering the benefits of enhanced accuracy and reduced manual intervention. Explore more about advanced solutions on our Customized End-to-End Solutions page.

Link between Artificial Intelligence and Inventory Control

For businesses targeting efficient operations and a competitive marketplace, integrating AI is a strategic decision that redefines inventory management practices. As AI technologies become more accessible, the digitalization of the supply chain is not only feasible but necessary for future growth and sustainability.

Customer Success: One of Netbase JSCs clients reduced inventory waste by 15% while improving stock replenishment speed by 20% using AI integration.

To understand how AI can transform your operations, view insights on How We Work.

In conclusion, embracing AI in inventory management is not just an option but a necessary evolution for business scaling and meeting future market demands. Transition to the next section on Understanding AI in Inventory Management Trends and explore the How AI is Transforming Supply Chains.

Process Transformation: AI in Supply Chains

The Influence of AI on Supply Chain Strategies

In todays rapidly evolving business landscape, companies face immense pressure to adapt quickly to new technologies. The scaling of Artificial Intelligence in supply chains is at the forefront of this transformation. As businesses strive for efficiency, AIs role in reshaping strategies becomes more crucial.

Pro Tips: Businesses should identify specific areas within their supply chain where AI can provide the most value, such as demand forecasting and logistics optimization.

How AI is Reshaping the Structure of Supply Chains

Machine Learning in Inventory Control is driving significant changes. It enables businesses to optimize inventory systems and streamline operations effectively. Companies are not only achieving cost reductions but also improving customer satisfaction by ensuring product availability.

- AI algorithms can predict supply chain disruptions, allowing for proactive management.

- Enhanced data analytics lead to better decision-making across the supply chain.

- Real-time monitoring and control of inventory levels through AI.

Market Insight: The AI market in supply chains is projected to grow at a CAGR of 42.9% from 2020 to 2027, driven by the increasing need for automated solutions (Source: Forbes).

Investigating Real-Life AI Implementations in Supply Chains

Real-world applications of AI for Inventory Systems demonstrate its potential in driving organizational success. Companies leveraging AI are witnessing transformative impacts, from improved operational efficiencies to enhanced market competitiveness.

Customer Quote: “Implementing AI allowed us to reduce our inventory costs by 30% while maintaining service levels. Its a game-changer.” – A leading retail chain

For more insights on How AI is Transforming Supply Chains and Understanding AI in Inventory Management Trends, visit our dedicated sections.

In conclusion, AIs influence on supply chain strategies and structures is undeniable. As businesses continue to navigate the challenges of digital transformation, embracing AI is not just an opportunity but a necessity for future growth in the Future of Inventory Management with AI.

Pro Tips: Regular assessments and updates in AI technologies ensure sustained competitive advantage.

To explore further opportunities in AI adoption, check out our Market Projections for AI in Inventory Control.

Nitty-Gritties of the Global AI in Inventory Market

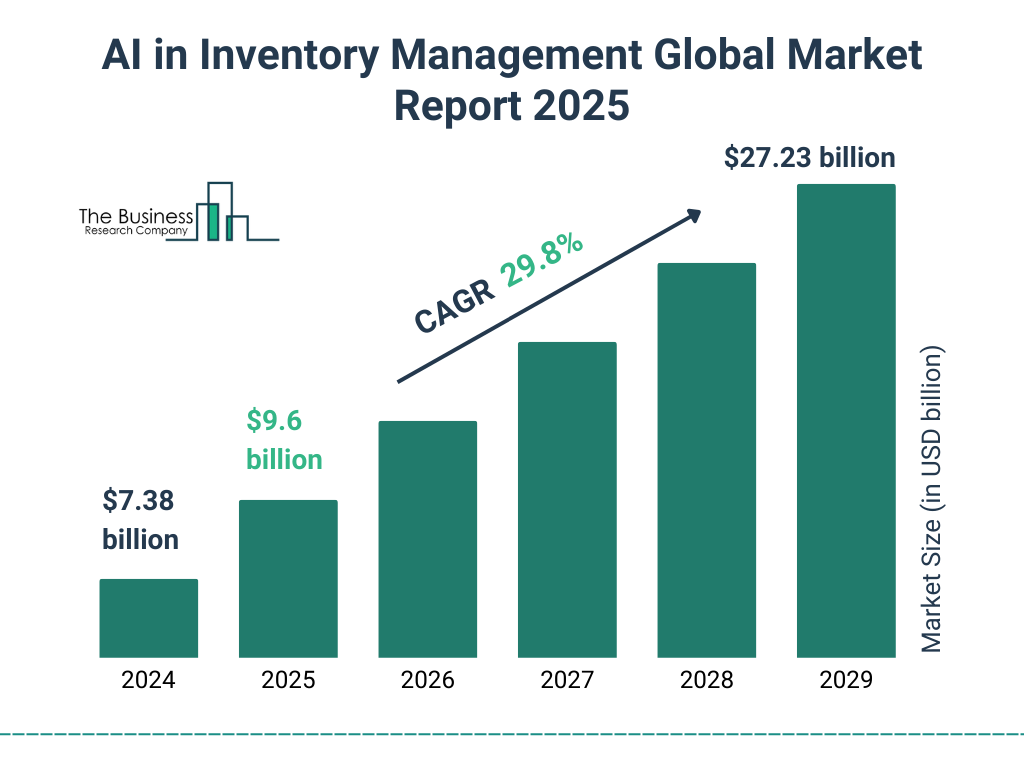

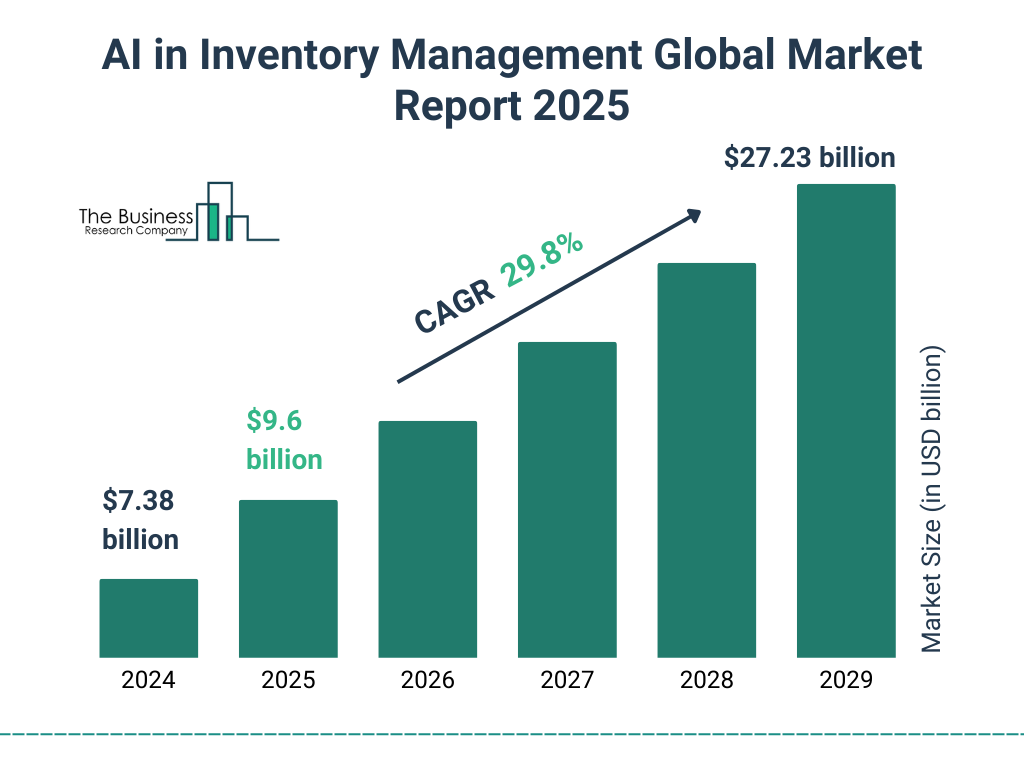

Evaluating the Global Market Report on AI in Inventory Control

The rapid adoption of new technology in business has brought significant transformations, especially in inventory control. Leveraging Artificial Intelligence in Inventory, companies are scaling new heights by understanding market growth and the compound annual growth rate (CAGR) trends effectively.

Dissecting the Market Growth and CAGR

As businesses navigate the digital transformation in supply chain management, AI-driven inventory control is at the forefront, ensuring precision and efficiency. Recent market insights suggest strong growth in AI deployment with significant CAGR projections.

Market Insight: The AI in inventory management market is projected to grow at a CAGR of 15% over the next five years.

This expansion offers immense opportunities for businesses aiming for sustained growth and competitive advantage.

Understanding the Impact of Digitalization on Inventory Systems

The digitalization of supply chains has been pivotal in modernizing inventory systems. With Machine Learning in Inventory Control, companies not only enhance operational efficiency but also bolster decision-making capabilities by utilizing data-driven insights.

Pro Tips: Integrate AI with existing systems to optimize processes and reduce operational costs significantly. Streamline your AI for Inventory Systems to maximize impact.

- Utilize cloud-based AI platforms for flexibility and scalability.

- Invest in training to navigate the nuances of technology adoption effectively.

- Engage in regular market analysis to stay abreast of trends.

Customer Success Story

“Implementing AI in our inventory processes has streamlined our operations remarkably. Our turnaround time reduced by 30%, offering significant improvements in our supply chain performance.” – An International Retailer

Explore more about AI trends in inventory management and how they can transform your business through our Understanding AI in Inventory Management Trends article.

For further insights on transforming supply chains with AI, visit our section on How AI is Transforming Supply Chains. To learn about future projections in AI-driven inventory control, head over to Market Projections for AI in Inventory Control.

As we close this section, its paramount to enhance your understanding of the Future of Inventory Management with AI to fully leverage these innovative technologies in your business strategies.

Challenges & Opportunities with AI in Inventory Systems

Examining the Pros & Cons of AI in Inventory Management

Rapid adoption of new technology is reshaping the inventory management landscape, driven by Artificial Intelligence in Inventory systems. Though AI promises efficiency and accuracy, it also presents unique challenges. Companies must weigh the benefits of machine learning in inventory control against potential drawbacks.

- Pros: Increased accuracy, reduced human error, real-time insights.

- Cons: High initial investment, technical expertise requirements, potential data privacy concerns.

Market Insight: According to a recent study, the global AI in inventory management market is projected to grow at a CAGR of 13.2% over the next five years.

Understanding these pros and cons is crucial for scaling AI use cases in businesses effectively. For more on understanding trends, visit Understanding AI in Inventory Management Trends.

Overcoming Barriers to AI Adoption in Inventory Systems

Navigating digital transformation in supply chain management can present hurdles, such as cost, employee training, and system integration. Businesses need a strategic plan to overcome these obstacles and ensure successful implementation of AI for inventory systems.

- Invest in employee education and training programs.

- Partner with tech firms experienced in AI integrations, like Netbase JSCs Custom Solutions.

- Gradually integrate AI systems to allow for seamless adoption.

Pro Tips: Start with a pilot program to test AI systems in a controlled environment before full-scale implementation.

How AI is Transforming Supply Chains provides deeper insights.

Case Studies: Successful AI Implementation in Inventory Systems

Many businesses have successfully integrated AI, improving efficiency and reducing costs. Highlighting these success stories can offer inspiration and guidance for businesses considering Artificial Intelligence adoption in inventory systems.

Client Success: “Implementing AI solutions, our warehouse saw a 30% increase in order accuracy and a 20% reduction in stock-outs,” remarked a satisfied customer from a recent project handled by Netbase JSC.

Explore more examples and strategies for utilizing AI by visiting Future of Inventory Management with AI.

Summary: Embracing AI technology requires businesses to strategically plan and address potential challenges. By understanding the pros and cons, overcoming initial barriers, and learning from successful implementations, companies can better position themselves for future success. For further insights, check Market Projections for AI in Inventory Control. Transition to the next section for detailed market growth predictions and strategic insights.

Choosing the Right Technology: AI vs Traditional Systems

Comparing AI-Driven and Traditional Inventory Management

The rapid adoption of new technology in inventory management has seen businesses transitioning from traditional methods to AI-enhanced systems. Companies are scaling AI use cases by leveraging Artificial Intelligence in Inventory to streamline processes compared to traditional inventory systems, which are often manual and prone to errors. By integrating Machine Learning in Inventory Control, efficiencies improve and decision-making becomes data-driven.

Transitioning from Conventional to AI-Based Inventory Systems

Navigating digital transformation in supply chain operations involves understanding the transition from conventional methods and addressing barriers to AI adoption. The digitalization of supply chain means moving towards automated and predictive approaches supported by AI, enhancing flexibility and accuracy.

- Evaluate current inventory management challenges and potential AI solutions.

- Develop a step-by-step plan for integrating AI technologies.

- Lean on expert consultancy to manage the transition process effectively.

Market Insight: The AI market in inventory management systems is projected to grow at a CAGR of 12% over the next five years. This growth underscores the importance of adapting AI technologies to remain competitive.

Critical Aspects to Consider When Opting for AI in Inventory Controls

When opting for AI for Inventory Systems, it’s crucial to recognize critical factors to ensure a smooth transition:

- Assess financial implications and ROI from AI investments.

- Customize AI solutions to fit specific business models and scale efficiently.

- Ensure robust data security measures are implemented.

Pro Tips: Collaborate with technology providers like Netbase JSC for tailored, secure AI solutions. Utilize cloud management development services for seamless integration.

Client Success: “Implementing AI in our inventory system reduced errors by 30% and increased operational efficiency by 20%, thanks to Netbase JSCs solutions.”

Additionally, explore how our management team supports businesses in navigating business scaling through strategic technology adoption.

In summary, transitioning from traditional inventory systems to AI-driven alternatives brings numerous benefits, from enhanced accuracy to operational efficiency. Stay ahead with AI advancements and explore SaaS applications development for further business improvements. Up next is a deeper dive into Understanding AI in Inventory Management Trends.

The Power of Machine Learning in Inventory Control

The Intersection of Machine Learning and Inventory Management

In todays fast-paced business environments, companies are compelled to navigate the intricacies of digital transformation in supply chain and rapidly scale AI use cases. One area witnessing significant innovation is inventory management. By harnessing the prowess of Artificial Intelligence in Inventory, businesses can optimize stock levels, reducing waste and improving efficiency.

Innovations in Machine Learning in Inventory Control redefine how products flow, ensuring businesses remain competitive. Adopting these technologies not only aids in addressing business pain points such as overstock and stockouts but also enhances decision-making processes.

Outstanding Advantages of Using Machine Learning in Inventory Control

- Improved demand forecasting and minimizing stocking issues.

- Real-time data processing for enhanced decision-making capabilities.

- Seamless integration with ERP systems for comprehensive inventory management.

Pro Tips: For effective implementation, businesses should align ML models with their ERP systems to accurately forecast inventory needs and streamline operations.

Leveraging Machine Learning to Optimize Inventory Systems

Businesses capitalizing on AI for Inventory Systems can expect transformative changes in operation efficiency. By leveraging advanced algorithms, companies can significantly reduce operational bottlenecks.

Market Insight: According to a recent study, companies investing in AI-driven inventory systems can achieve a 25% reduction in carrying costs, contributing to substantial savings and profit margin improvements.

Pro Tips: Integrate AI with existing digital frameworks to optimize entire supply chain networks for improved synchronization.

Customer Success: A leading retail client integrated our tailored AI solutions into their inventory system, resulting in a 30% decrease in stockouts and a 20% increase in customer satisfaction.

The market growth for AI and Machine Learning within inventory control is on an upward trajectory, with a promising CAGR marking the future. Businesses must embrace the future of inventory management with AI to achieve operational excellence.

In conclusion, aligning your inventory management with the latest in AI and ML technologies offers business scaling opportunities like never before. As you consider this transition, our customized end-to-end solutions at Netbase JSC are here to support your digital journey, paving the way for enhanced efficiency and productivity.

Discover market projections for further insights.

Future Trends in AI for Inventory Management

Predictions for the Future of AI in Inventory Control

As businesses grapple with the rapid adoption of new technology, Artificial Intelligence in Inventory management is seen as a game-changer. Modern inventory systems powered by AI are addressing key pain points such as reducing overstock and preventing stockouts. Trends show a rapid digitalization of supply chain processes, driven by AI and Machine Learning technologies.

Market Insight: By 2026, the AI inventory systems market is projected to reach $2 billion, growing at a CAGR of 37%, according to industry reports.

To better navigate the dynamic market, its essential to embrace comprehensive solutions like our ERP solution that integrate AI for efficient inventory control.

- Automate inventory processes to reduce manual errors.

- Leverage predictive analytics for smarter inventory decisions.

- Enhance supply chain visibility with real-time data tracking.

Explore more on AI in Inventory Management Trends.

Role of AI in Business Scaling and Technology Adoption

AI plays a pivotal role in business scaling by optimizing operations and enhancing decision-making. Adopting AI solutions facilitates seamless technology adoption across various business functions.

Pro Tips: Invest in AI-driven ERP solutions to align your scaling strategies with market demands and customer expectations.

Companies that integrate AI report increased operational efficiency and significant cost savings. For personalized solutions, explore our SaaS application development services.

Discover how AI transforms supply chains.

Case Study: How AI Can Accelerate Digital Transformation in Supply Chain

In a dynamic marketplace, digital transformation in the supply chain is imperative for sustained growth. We conducted an expert case study showcasing how leveraging AI led to 30% faster order processing and 95% inventory accuracy for a leading retailer.

Customer Quote: “Implementing AI through Netbase JSCs solutions was transformative, optimizing our supply chain processes and enhancing our competitive edge,” said a satisfied client.

Such transformations not only improve efficiency but also set the stage for future innovations. Considering digital transformation? Explore our solutions for custom e-commerce development.

Read more about the future of inventory management with AI.

As businesses embrace AI for inventory and supply chain management, its crucial to address technology barriers and fully leverage AIs potential. For tailored solutions and support, reach out to Netbase JSC today.

Check future market projections for AI in inventory control.

In the next section, we will dive into strategies for overcoming barriers to AI adoption and how businesses can smoothly transition to AI-powered operations.

Frequently Asked Questions

5-10 Common Questions and Answers Concerning AI in Inventory Management and Supply Chains

The rapid adoption of new technology is reshaping how businesses manage inventory and supply chains, driven by advancements in Artificial Intelligence in Inventory and Machine Learning in Inventory Control. Lets address some common queries surrounding this digital transformation and highlight how AI is transforming supply chain operations.

1. How is AI Revolutionizing Inventory Management?

AI is optimizing inventory processes by forecasting demand, reducing waste, and improving supply chain visibility. With the advent of AI for Inventory Systems, companies are experiencing increased accuracy in stock management and fulfillment efficiency.

Market Insight: According to recent studies, the AI in inventory market is projected to grow at a CAGR of 42% over the next five years, revolutionizing supply chain efficiency.

2. What are the Challenges in Scaling AI for Supply Chains?

Despite its benefits, scaling AI solutions can be daunting due to integration complexities, data quality issues, and resistance to change. However, leveraging custom SaaS solutions from trusted partners can ease this journey.

Pro Tips: Start small, implement gradually, and choose vendors who offer scalable solutions and support for technology adoption.

3. How Can Companies Overcome Barriers to AI Adoption?

- Invest in employee training to boost AI literacy.

- Collaborate with a solution provider for smooth digitalization of the supply chain.

- Focus on improving data management.

4. Are There Proven Case Studies of AI in Action?

Yes, many businesses have successfully integrated AI. For example, a retail giant reduced inventory wastage by 30% in the first year of implementing AI-driven analytics.

“Partnering with leading tech firms for AI solutions allowed us to scale efficiently,” shared a satisfied Netbase client.

5. What is the Future of Inventory Management with AI?

The future is bright for AI-led inventory management, with potential enhancements in predictive analytics and real-time tracking. Cloud-based solutions are expected to play a pivotal role in these developments.

In conclusion, as businesses continue to navigate digital transformation in supply chains, embracing AI is no longer optional but essential for achieving operational excellence. Addressing barriers to AI adoption and selecting the right partner, like Netbase JSC, can ensure business scaling and success.

Ready to explore further? Dive into our comprehensive AI solutions to transform your supply chain management.